It probably never crossed your mind, but did you know that by simply replacing an often overlooked part in your car, you can improve not just its performance, but also your health and the environment?

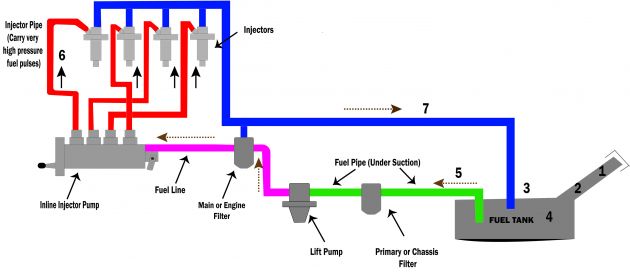

We’re talking about your car’s fuel lines and the hoses that make up the fuel system. In a nutshell, the fuel lines take fuel from your vehicle’s tank – via a fuel pump – to the electronic fuel injection (EFI) system used by all modern cars. The injected fuel is ignited in the combustion chamber and generates the energy required to power the car. The fuel line consists of hoses with tubing and other components.

Petrol is highly flammable, which is why ensuring the integrity of a vehicle’s fuel lines is extremely important. As you can imagine, even a small leak has the potential to be disastrous, as it may result in fumes entering the cabin, fuel spills or even result in a vehicle fire.

Aside from leaks, the rubber fuel lines may degrade from the inside and the resulting particles can break free and clog up the fuel injectors. This could lead to engine inefficiency power loss, check engine lights coming on, or even engine damage due to lean misfires.

Degradation aside, old rubber hoses can harden and crack, or pinhole leaks can occur, just like other wear-and-tear rubber bits in your car. Also, thinning hoses allow fuel and volatile organic compounds (VOCs) to slowly “escape out” (permeation), leading to fuel wastage and damage to the environment.

Zooming in on the latter, the said VOCs have been proven to contribute to ground level ozone, also known as bad ozone. While ozone in the stratosphere protects us from harmful UV rays, ground level ozone can trigger a variety of health problems including chest pain, coughing, throat irritation, and airway inflammation. It also can reduce lung function and harm lung tissue. Ozone can also worsen bronchitis, emphysema, and asthma, according to the US Environmental Protection Agency.

The California Air Resources Board (CARB) has banned the use of general purpose fuel line hoses which have a high permeation rate. The Golden State is a world’s leader in emissions/green regulations and many US states have followed CARB’s lead. As California is a large market for cars, CARB regulations also impact the entire global automotive industry.

The ability to withstand pressure is another factor. Modern EFI engines inject fuel under high pressure and the hoses carrying the fuel need to have a suitable working pressure for safety purposes. Fuel line hoses are designed and manufactured with different specifications for different applications. There’s pressurized fuel (from fuel tank to the fuel injector) and also low pressure (return to fuel tank); both need different fuel line hose specifications.

Fuel injection hoses are heavier duty than hoses used elsewhere in the fuel system. Hoses that are submersible in the fuel tank need to have different specifications as well; they are required to withstand the effects of petrol on the outside.

A more recent development is the emergence of “aggressive fuels” such as petrol with high ethanol blend in the US, as well as biodiesel. Compared to pure petroleum-derived fuels, the chemical composition of these aggressive fuel blends have been shown to degrade basic rubber (dry, soften, stretch or crack) found in general purpose fuel hoses. Therefore, modern fuel hoses with multi-fuel compatibility are needed for modern fuel, the experts say.

It’s undeniable that effective fuel line hoses are important for both performance and safety, and there are various types to suit different applications. When it comes to something as vital as this, it pays to opt for items made by reliable and established OEMs, over the cheapest item available.

Gates is a company with more than 100 years legacy of innovation and engineering excellence, offering an extensive range of high quality fuel line hoses. As an original equipment manufacturer (OEM) for leading vehicle manufacturers worldwide, Gates continually invests in R&D and technology so its products not only outperform industry standards; they exceed customers’ demanding expectations.

Fuel line hoses must be tested and certified by the US-based Society of Automotive Engineers, and approved products carry the SAE rating. The Gates Extend SAE J30 R6 fuel hose is designed to carry automotive fuel and to operate in temperatures ranging from -30°C to 100°C. Recommended for fuel suction and for general usage in contact with fuel, this hose is dual spiral wrap reinforced.

The Gates SAE J30 R7 fuel line hose is designed to operate at higher pressures and temperatures. The inner tube is made of NBR/PVC with an outer cover of CSM and reinforcing made of Kuralon synthetic fibre. It conforms to SAE J30 R7 specifications and is suitable for the aggressive fuels mentioned above, such as ethanol blended gasoline E20 and E85.

The Gates SAE J30 R9 fuel injection hose is designed specifically for high pressure fuel injection lines. Engineered to resist E10/E20/E85 petrol blends, diesel and biodiesel, the inner tube is made of FKM and the cover by Hypalon. This SAE J30 R9 specification hose withstands deterioration from oxidized gas which forms in fuel injection systems.

Fuel line hoses are typically good for up to five years, and long use might cause internal flaking that will clog up the fuel injection system. This may happen even if the hose exterior looks fine. So, if you’re refurbishing an older car, buying a used car, or have simply overlooked these small but vital wear-and-tear parts in your car maintenance schedule – remember that replacing your fuel line hoses with quality products from Gates would not only improve your vehicle’s health, but also yours and the environment’s.

Source: Read Full Article