Daimler put its third (out of nine planned) battery pack production facilities into operation.

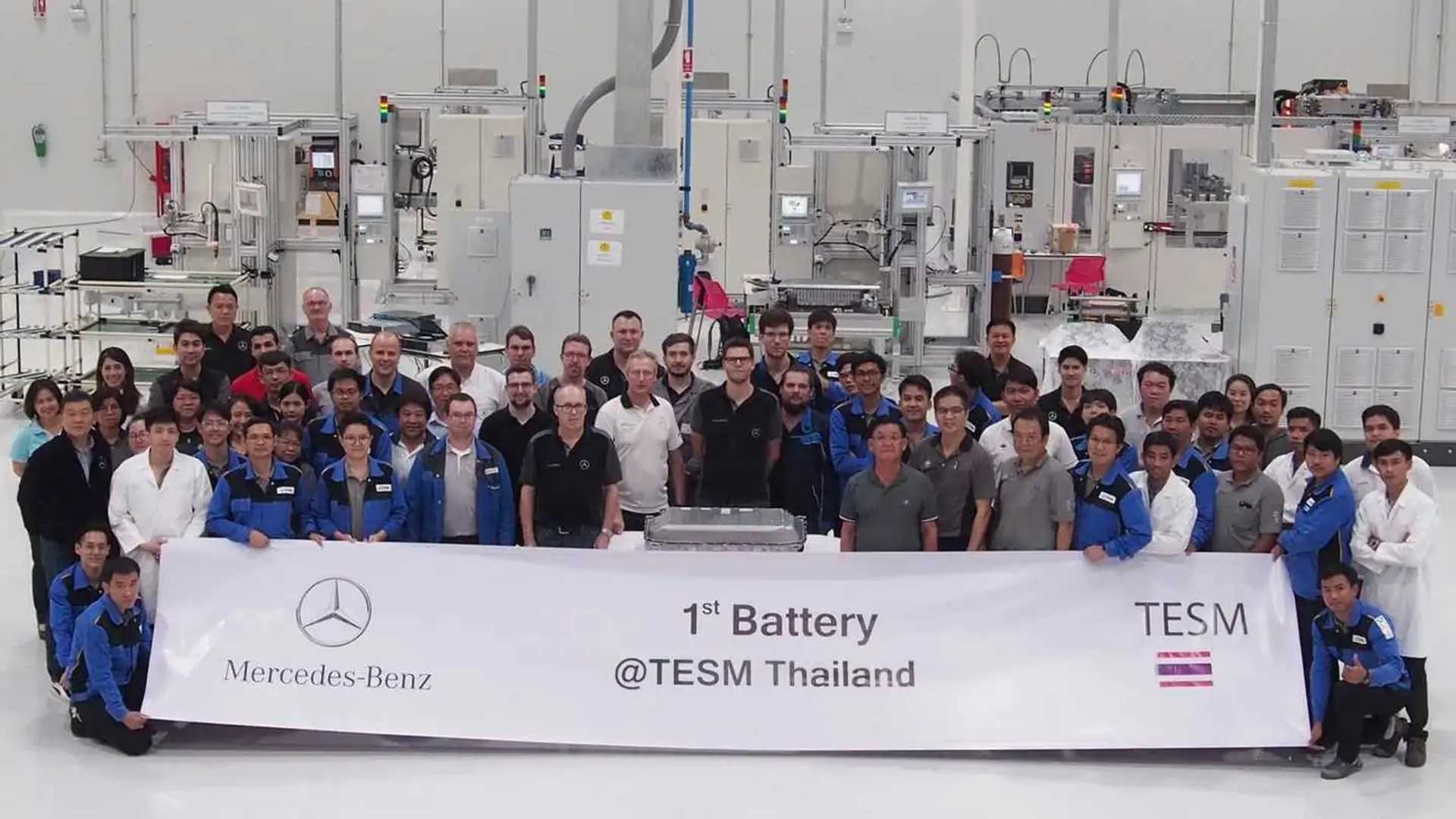

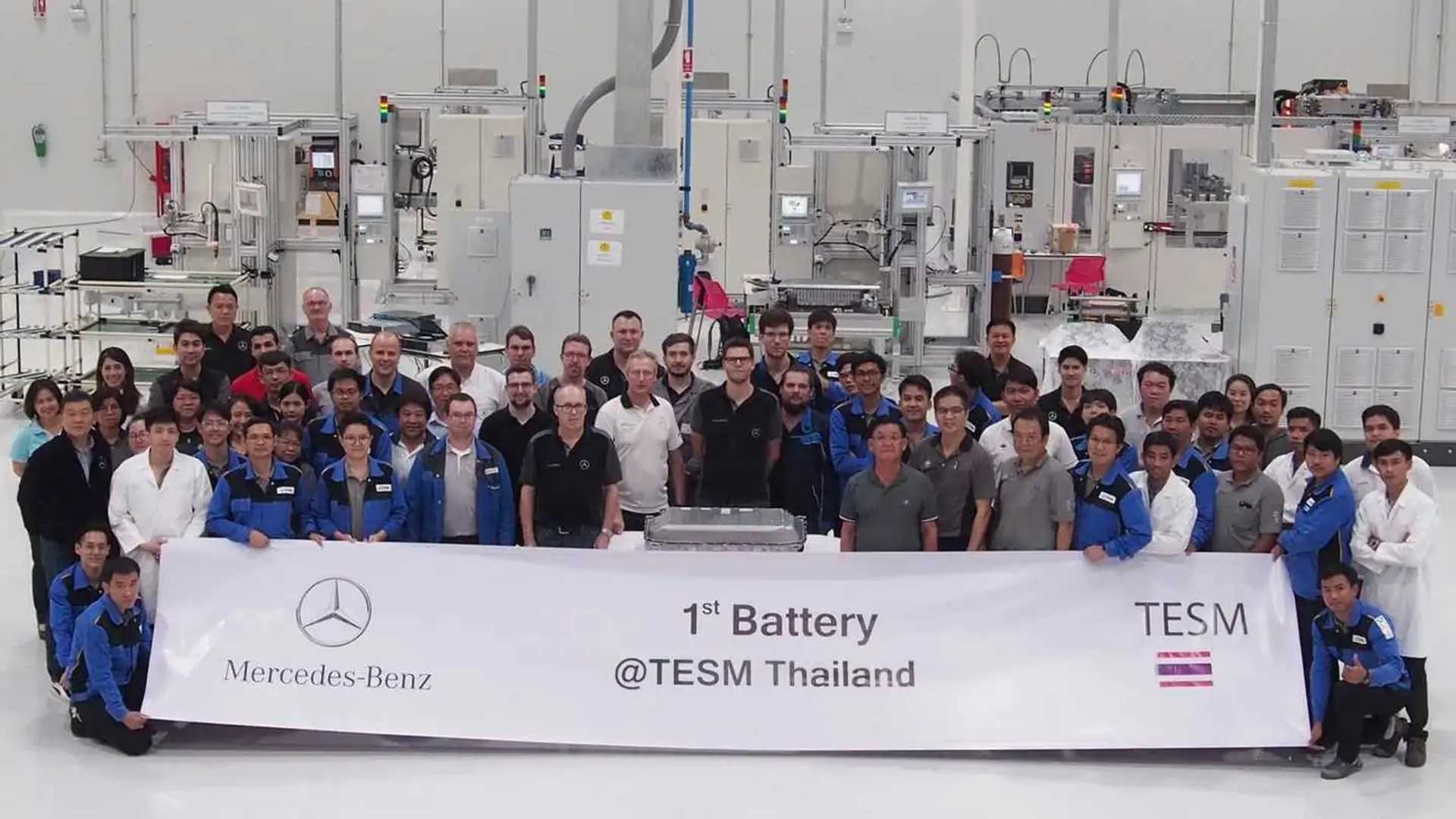

Mercedes-Benz has announced the start of battery pack production for plug-in electric cars in Bangkok in Thailand, which was promised in 2018.

Through an investment of more than €100 million ($111 million), the German manufacturer, together with local partners Thonburi Automotive Assembly Plant (TAAP) and Thonburi Energy Storage Systems (TESM), expanded the plant and added a battery pack facility.

The PHEV packs will be used among others for the Mercedes-Benz C-Class, E-Class, S-Class, GLC and GLC Coupé, which are locally assembled. According to the press release, especially the C- and E-Class, are in particular demand in Thailand.

A similar move was done recently by BMW, which makes us wonder whether there are some special incentives to launch battery pack production or it is just the same strategy.

“The Mercedes-Benz plant in Bangkok in Thailand has started local production for Mercedes-Benz plug-in hybrid-batteries. The new battery factory was built on a 50,000 m² site located at the vehicle manufacturing plant in the Bangkok region. In addition, the existing automotive plant has been expanded. Mercedes-Benz AG has invested more than 100 million euros together with local partners Thonburi Automotive Assembly Plant (TAAP) and Thonburi Energy Storage Systems (TESM) for the plant extension and the battery factory. In total, more than 300 new jobs are created, 100 of these jobs are created in the battery production. The production facilities are highly standardised and flexible. As a result, they can be adapted to local market conditions in a short time. With the joint investment in the new factory building as well as the factory extension, Mercedes-Benz AG and the local partner TAAP are once again strengthening their cooperation.”

Gallery: Mercedes-Benz Cars starts local battery production in Bangkok

5 Photos Daimler has decided to build an entire network of localized battery module/pack plants. Through an investment of more than €1 billion ($1.1 billion), the company will put on-line 9 battery pack plants at 7 sites on three continents: “The first factory in Kamenz is in series operation. The second factory in Kamenz (Germany), the battery factory at the Beijing site (China) and in Bangkok (Thailand) started series production in 2019. The battery factories in Stuttgart-Untertürkheim (Germany), Tuscaloosa (USA) and Jawor (Poland) will start at the beginning of the next decade. The local production of batteries is an important success factor in Mercedes-Benz Cars electric offensive and the crucial building block for handling the global demand for electric vehicles flexibly and efficiently. The battery is the heart of all electrified drives. The complex battery systems from Mercedes-Benz are assembled and tested in the international battery factories. Mercedes-Benz buys the battery cells flexibly on the world market and secures access to the latest technologies on the market.” Source: Read Full Article