The Shelby name is tightly associated with Ford nowadays, but there was a very short time when it was trying to be its own manufacturer. Rather than using pre-produced cars and stuffing high-powered engines in them, Shelby wanted to build a sports car in-house, inspired by the basic idea of the original Cobra. The result was a short-wheelbase, open-top coupe with a powerful V-8 under its hood. In 1997, it showed off a concept sample that would go on to become the Shelby Series 1. It looked to be a brilliant modern-day Cobra successor on paper, but the reality would prove to be a bit different.

Thanks to this Series 1 going up for auction at Mecum Kissimmee, we have an opportunity to look back on the development of this car, of which only 294 of the proposed 500 were built.

The Lead Up to the Series 1

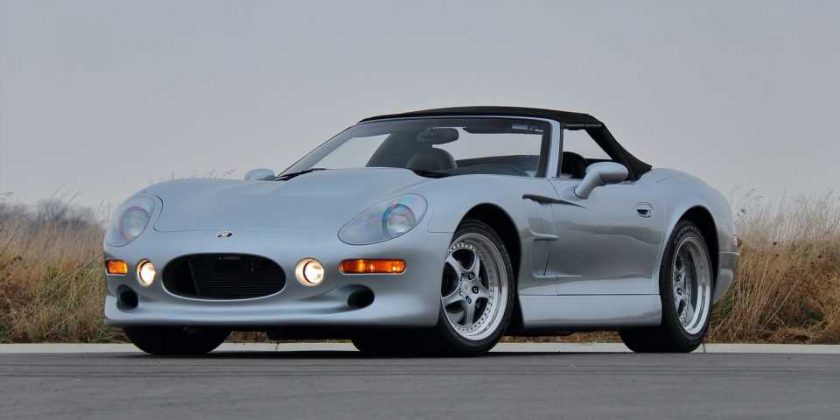

Imagine sitting at the Los Angeles Auto Show in 1997 after hearing rumors that a brand-new Cobra was in the works, and you were greeted by the prototype of the Series 1. It looked exciting sitting still, with a clean new design, short wheelbase, open top, fender haunches, and of course a V-8 under its hood. How could it go wrong?

But things started to take a turn even before the first prototype was built. Despite much of the claim that Carroll Shelby had designed and built the Series 1, the reality was his health was deteriorating thanks to late complications with his kidney from an earlier heart transplant in 1990. He was directly involved in its initial design, but the process of the prototype’s manufacturing was done while Shelby was in the hospital. This left the building of the Series 1 to Shelby American with major backing and influence by General Motors, specifically its Oldsmobile division.

The Aurora V-8

It was that Oldsmobile influence that steered the Series 1 toward using a brand-new V-8 engine from General Motors, the L47 Aurora. It was a 4.0-liter engine with a double overhead cam (DOHC) valvetrain layout and could produce up to 250 hp and 260 lb-ft of torque in street guise when it was used in the rather tame-looking namesake sedan, the Oldsmobile Aurora. The idea behind this push, as viewed by Oldsmobile, was to create a car equal to the Corvette using their new V-8 but without the Olds badge, so as to not look like they were competing directly with the General’s sports car—especially because a modified version of the engine was already in use in sports car and open-wheel racing by the time the two Shelby Series 1 prototypes were built. Also, having a Shelby with an Oldsmobile V-8 under the hood as a pace car and leading the field of Indy Racing League cars with those racing-spec L47s during the Indy 500 was just icing on the marketing cake.

However, the weak 250-hp output wasn’t enough for Shelby American and their modern-day Cobra. It was going to be bumped to 350 hp and 290 lb-ft of torque and feed that power through a torque tube leading to the ZF six-speed transaxle while the engine itself was mounted directly behind the front axle for a modern front-mid-engine placement. Shelby would also plan to add on a supercharger to push it beyond 450 hp as an installed option, but that would cost more than $35,000 on a car that would go on to cost more than $100,000 in 1997 money—nearly $186,000 in today’s dollars. Which also means the equivalent price of that supercharger upgrade would be nearly $65,000.

Bespoke Chassis and Body, Parts Bin Interior

The chassis was rather impressive and modern (even by today’s standards), as it was built out of extruded and formed 6061 T4 aluminum that was all welded together. The chassis would then be heat-treated to bring its strength back into spec for strength and rigidity. Aluminum panels would then be bonded to create the floorboards and rocker panels for additional structural strength where needed.

The body was formed out of carbon fiber and fiberglass composites and fit over the massive 18×10 front and 18×12 rear wheels—three-piece Speedline units made from forged aluminum—with Goodyear Eagle F1 tires in 265/40ZR18 front and 315/40ZR18 rear. Bringing them to a stop were a set of two-piston front and single-piston rear calipers with a 13-inch front and 12-inch rear discs. Those wheel movements were controlled by a double wishbone and cantilever suspension system that transferred those motions to the centrally located coil-overs with remote reservoirs.

Every bit of that description sounds so perfect and what a modern Cobra should be, but it also had modern amenities attached to it, like power brakes, air conditioning, cruise control, traction control, stability control, power windows, and even a radio. Even with all of that, the Series 1 would have only weighed 2,650 pounds. (The actual curb weight would be significantly more due to late additions that added poundage.)

There were just some very glaring problems early on when it came time to create the production version of the Series 1. The first major hurdle was time. Although the prototype made its debut in 1997, production wouldn’t roll out until 1998, and it was sold as a 1999 model year. This meant the Series 1 had to conform to the updated Federal Motor Vehicle Safety Standards for 1999; that increased the cost of production, which trickled down to the eventual sale price. The Shelby American team building the cars were also under-resourced and overworked, even before production started. There was also the trouble due to its ties to GM, as the Series 1 didn’t just use the Aurora V-8. The climate controls came from Pontiac, it used a Camaro gauge cluster, the radio is from Buick, the sound system came from Delco under the Monsoon brand, and a slightly modified windshield was borrowed from Corvette. The cost Shelby was demanding just didn’t match the interior they were selling.

Tricky Handling

On the road and the test track, the Series 1 was a bit of a mixed bag. When driven hard, the car proved to be mostly predictable thanks to good front-to-rear weight balance. When we took it for a drive back in 1998 at Las Vegas Motor Speedway’s interior road course (which uses part of the main oval), C. Van Tune—writer of our review at that time—said it was like “driving a continental plate.” He continued, “The 50/50 weight balance helps give the Series 1 a very neutral feeling, but the front tires can turn into pushers (such as in a Viper or Vette), given too much throttle. Lift the throttle just a bit, and the rear comes out just enough to cancel the push; come off more, and it’ll step out further, giving the indication it wants to spin, but it won’t unless you really get in over your head.”

Unfortunately, Van Tune was encouraged to push beyond that limit by photographer Randy Lorentzen: “Entering turn one after the straightaway at about 100 mph, I blip down two gears (not easy with the current shifter) and toss the car into a mad drift that’s picture-perfect for all of 2 seconds. Then she comes around. Fast. And I ain’t catching it. Determined not to be remembered as the guy who put Carroll’s million-dollar car into the pucker bushes, I manage to gather it up just before I run out of tarmac. No harm, no foul. Studying the photos later, I discover the right front tire was completely off the ground just before the car let go.”

Other weaknesses were the difficulty to get the engine to properly rev-match, the gear whine of the ZF transmission, and heavy braking modulation with front wheel lockup (as there wasn’t any ABS on that car). It took 129 feet for it to stop from 60 mph and 14.7 seconds in our 0-100-0-mph test. Unbeknownst to Van Tune, it turns out the aluminum casting that supported the rear suspension cracked not once but four times before he sat down to drive it, and the one on the car we tested was welded back together. Shelby didn’t have time to get a fifth one because the casting was made in Toronto, and we know this now thanks to Eric Davidson’s book on the Series 1, called Snake Bit.

Further production issues stemmed from the heat treating of the welded aluminum chassis. The jigs used by Shelby’s team weren’t strong enough and allowed the chassis to warp as it cooled, pushing manufacturing behind even further to find stronger jigs. Although Oldsmobile partnered on supplying the engine, it refused to give Shelby’s team the computer coding that would allow it to tune the ECM. Now, instead of that 350 hp Shelby originally wanted, the engines were only able to muster 320 hp.

The Beginning of the End

The next nail was that production had now shifted to Venture Industries (no, not that one), a company that had bought out Shelby American during production of the Series 1. Venture discovered the side windows and convertible tops didn’t fit properly, which then had to be fixed during production and increased production costs even more. The bad news there was that the Series 1s in production had already been sold to an agreed to price, so those new costs couldn’t be passed down.

During painting, it was discovered that the composite bodywork wasn’t completely sealed, which allowed paint to flow into the pores that developed. Venture’s solution was to use body filler, increasing the weight of the carbon body panels and pushing the car into the 3,000-pound weight range. Those body panels were also hand-adjusted with shims while the cars were on the production line (which sounds oddly familiar). Finally, the ZF transaxle would also have issues with faulty units, shift linkage issues, and oil leaks, which required repair or full replacement before being shipped out.

By the time production was sorted out, Oldsmobile had folded, and Carroll Shelby bought the rights to the Series 1 back from Venture Industries. Worse yet, those cars that weren’t finished could only be sold as kit cars, as Shelby could not get an extension for federal safety standard exemptions. In all, only 249 of the proposed 500 units were ever sold as complete vehicles. Although production of the Series 1 did continue until 2005, cars built after 1999 were not factory complete and required sourcing of engines and transmissions.

The 1999 Shelby Series 1 at Mecum Kissimmee

With only 249 cars ever produced, the 1999 Shelby Series 1 tends to commands a high price when they come up for sale despite the various issues described above. These cars have a a median value of $117,700 but have gone as high as $313,000 for one owned by Carroll Shelby (CSX 5001, making it the very first production Series 1) and sold in 2018. In 2022, nine Series 1s have crossed auction blocks with sale prices ranging from $105,000 to $242,000, and this one should be very close to that higher number.

This particular model is number 174 (chassis code CSX 5174) and only has 2,275 miles on its odometer. It comes in its original Centennial Silver (a paint that is also another parts-bin item from Oldsmobile) and original black interior. And it is a great example of the promise of the car. Its early issues may have doomed the Series 1, but the late-production cars hinted at what could have been.

With a less troubled history, maybe the Series 1 could have had a future, providing an alternate-universe competitor to various American high-powered sports cars of today. Instead, you’ll have to make do with this piece of history, which will cross the auction block at Mecum Kissimmee, which takes place January 4 to 15, 2023.

Source: Read Full Article