Almost half of the price of a new I-PACE… in the best case scenario.

Repair and maintenance of electric cars is largely an uncharted topic since the majority of the electric cars on the roads are almost new (probably less than 3-4 years old). Here we will take a look at a story of a one-and-a-half-year-old Jaguar I-PACE in Norway with a damaged battery enclosure (bottom plate) – see the hole in the image above.

The cause of damage is not known (the hypothesis is that it was caused while changing tires), but regardless of the cause, the repair turned out to be very expensive.

According to motor.no‘s article, two Jaguar’s service centers were willing to replace the battery enclosure for 337,000 NOK (€32,650/$39,319) or 356,000 NOK (€34,491/$41,571)! That’s almost half of the price of a new car – 700-800,000 NOK.

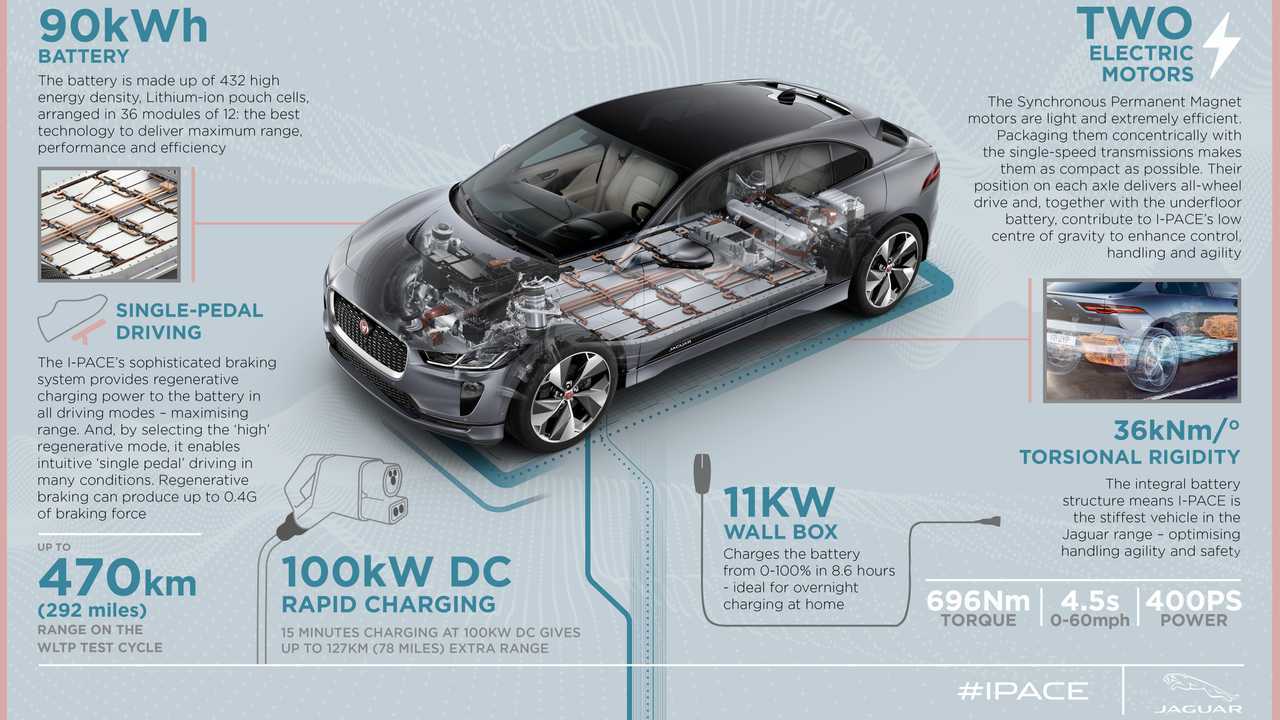

Moreover, it’s only the base case scenario, because if some of the battery modules are damaged (there are 36 of them), it would cost even more.

One might wonder, why is it so expensive? Well, the strict manufacturer’s guidelines require the use of an expensive sealant/thermo paste to protect and insulate the battery pack when replacing the battery box. The cost of the sealant alone is 130,000 NOK (including VAT tax) (€12,611/$15,197). Then there is the cost of a new battery box and the cost of labor.

If any of the modules or other parts inside are damaged too, the cost would be even higher!

Damage like this is not covered by the warranty, but the lucky owner was able to use his insurance, but solving the problem took two months!

It’s a single case, but according to the article, a representative of the insurer said there ares multiple similar cases of electric cars with damaged bottom plates/battery boxes. In some cases, the cost is so high compared to the value of the vehicle, that those EVs are scrapped. It’s a general industry problem.

Well, an interesting case we must admit. Hopefully, there will be a solution to keep the repair costs down to a reasonable level or we will have to deal with high insurance costs.

On the other hand, if the repair cost is so high, maybe then Tesla is right to simply make a structural battery as there will be no economic sense for repairs anyway?

Source: Read Full Article