And is significantly lighter.

Remember when Chris Harris criticized Toyota for developing the new Supra in cooperation with BMW when the GR Yaris is so good and developed entirely in-house? With Toyota’s participation in the World Rally Championship and other motorsport series, it’s more than obvious that the Japanese squad has the knowledge to build sports cars on its own. And they are pretty good at it.

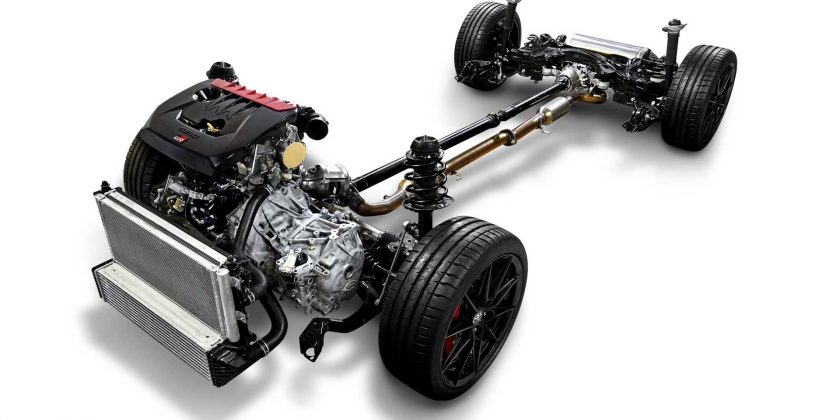

A new press release from the automaker details some of the special measures taken during the development of the GR Yaris, once again proving Toyota has rich expertise. For example, in order to build a highly rigid body that’s the foundation of a good driver’s car, the engineers put 259 more welding points compared to the standard new-generation Yaris.

Gallery: Toyota GR Yaris bespoke bodywork

In addition, Toyota explains, further improvements were made to the construction of the car using a total of 35.4 meters of structural adhesive compared to 14.6 meters in the standard hatch. Also, the GR Yaris is the first production Toyota to get a forged carbon composite roof, which saves 7.7 pounds (3.5 kilograms) compared to a steel panel roof.

Speaking of weight saving, the performance hatch also benefits from the extensive use of lightweight aluminum, which shaves off almost 53 pounds (24 kilograms). In combination with other weight-saving measures and the high output of the three-cylinder engine under the hood, the GR Yaris has more than double the power-to-weight ratio of the standard Yaris.

The fact that the sports hatch is the only one in the new Yaris’ family to be offered with just two doors has its very simple explanation. The body is specifically designed to meet the requirement of the WRC competitions.

Source: Read Full Article